We Are a Certified 508A Panel Facility

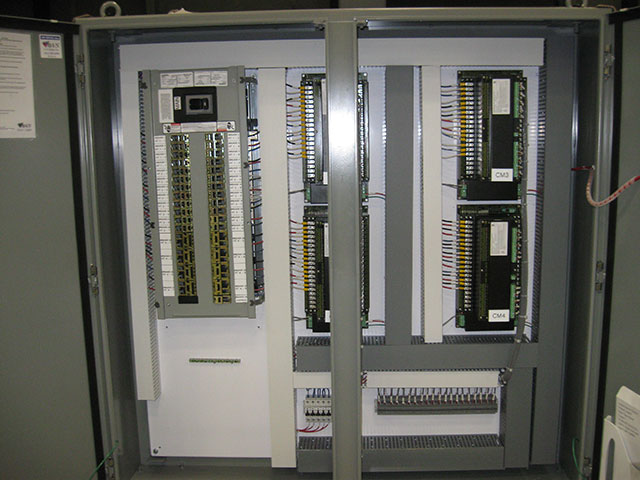

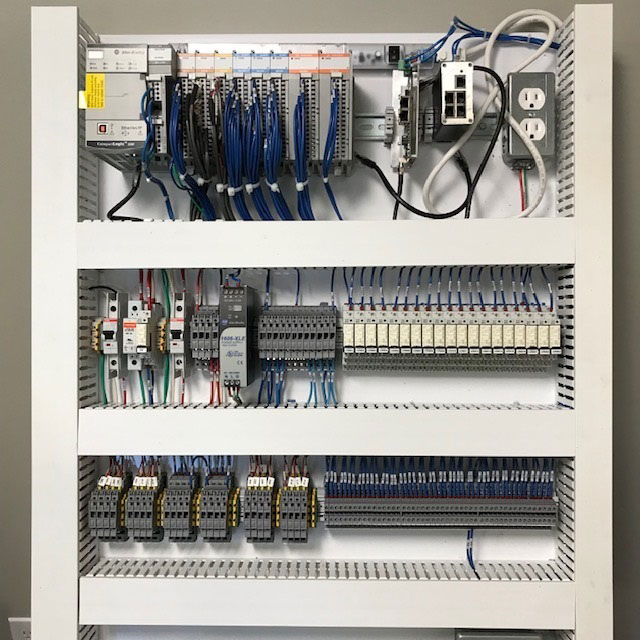

We are proud to be a 508A certified panel facility and will custom build single or production control panels to your specifications. These panel types include but are not limited to:

- PLC Control Panels

- Motor Control / VFD’s

- User Interfaces

- Analyzer Enclosures

- Temperature Control Panels

- Network Racks

- Local Control Stations

- Bubbler Panels

SCADA Panels

A.W. Schultz designs and builds all control panels used in our own integration projects. AWS is an UL 508A listed control panel shop. We fully factory test all control panels and control systems before they are shipped to the job-site. Testing is a priority on every system we build. No project is outsourced for any aspect of the build. This ensures a streamlined project and quality control.

Custom Solutions

AWS can assist a customer in designing a control or other panel to meet their process needs. By providing us with a description of the process and operation required with the panel, we can design and specify the best system for the job and as budget requires. All panels out of our shop are built to the UL508A standard for industrial control panels and come bearing that label. Whether you require one panel or many, we are able to assist.

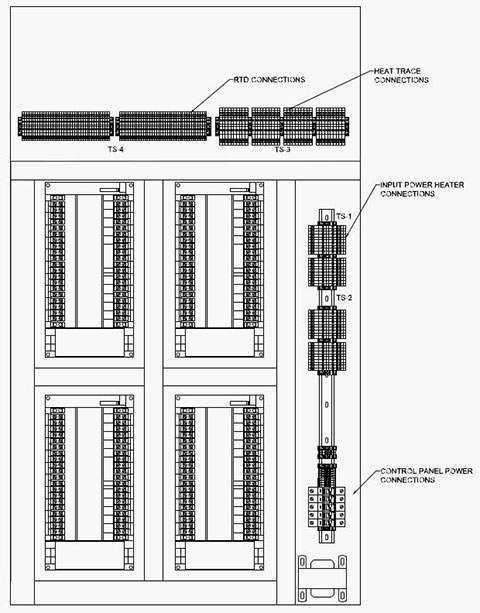

Heat Trace Control Panels

Our iTrace division provides highly intelligent custom-built control panels that include several unique features. Power limiting manages the inrush current and staggered start directs the power start-up circuits. All heat trace controllers have NEC required ground fault circuits which integrates ground fault equipment protection and eliminates the need for high cost specialty breakers. They can be designed to provide heating circuit up to 100A @ 600 VAC and up to 100- heat trace circuits in one package.

Our heat trace controllers include essential features that offer critical information in monitoring your heat trace:

- CONTINUOUS MONITORING – Monitors the electrical current usage as well as temperature and can alarm you when your heat trace is not working.

- DAILY TESTING – Your circuits will be tested on a daily basis and will notify you if faults are detected to initiate preventive maintenance.

- OUTSIDE DISPLAY – Viewing and adjusting of temperature, current set point information, alarm messages and system status information are all visible on the outside of the panel door.

- COMMUNICATION – Your existing centralized plant control system can communicate with your heat trace panel through Modbus, Profibus or Allen- Bradley EtherNet/IP.

Choose from 10, 20, 30 or 40 circuit panels with many different options of controls. Each heat trace controller is unique and custom built to meet the specifications of your project. You can even include an option with remote monitoring capabilities. For more information visit https://heattracecontroller.com

Heat Trace Retrofit

If you do not need a complete iTrace control panel, we can provide made to order retrofit subpanels. The CM2 Replacement for Nelson™ CM2 is an economical way to upgrade your existing heat trace controller. With the retirement of Nelson CM2, the parts for these units are no longer available. iTrace can provide a custom subpanel leaving your existing enclosure, conduit and wiring in place. We can also provide a retrofit kit to replace your current CM2 display located on the enclosure door.

Let us help you upgrade your old Nelson CM2 with a new CM2 Replacement. These retrofit options are also available for other manufacturers as well.